|

The MRP module will assist a company in maintaining sufficient levels of stock to satisfy future demands by bringing together information from Sales Orders, Purchase Orders, Works Orders and Stock Control. It can also assist a company to maintain optimum levels of stock based on re-order or minimum levels. There are three main processing options, Purchase Orders, Works Orders and Stock Transfers.

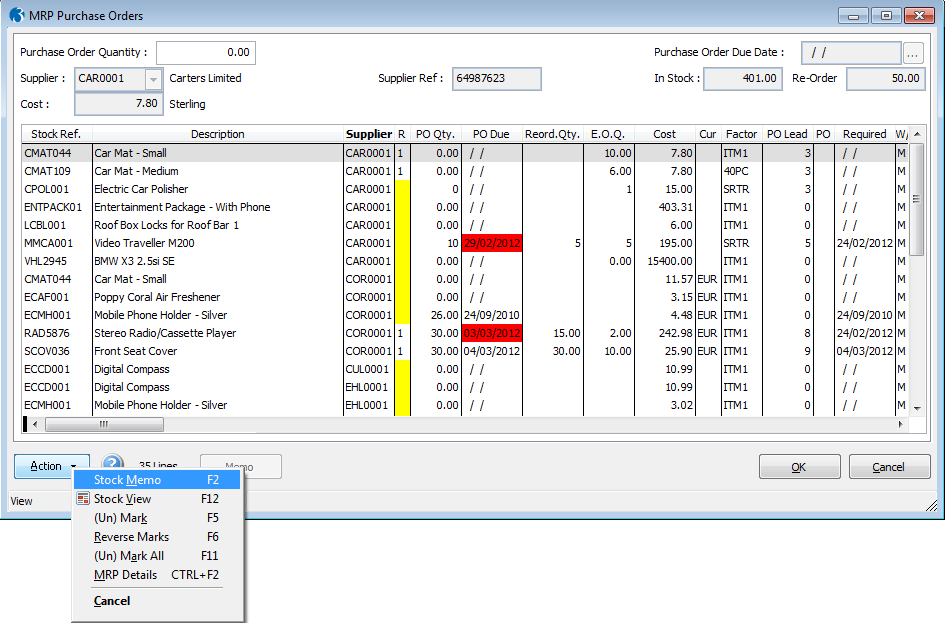

The Purchase Orders and Works Orders will highlight potential issues with stock levels by suggesting the creation (under stocked), cancellation (over stocked), adjustment of required quantity (over or under stocked). It can also suggest bringing forward or putting back the required by date of existing Purchase Orders or Works Orders.

The Stock Transfers process will suggest transferring available stock from one warehouse to satisfy demand in other warehouses.

Users can see projected stock available at particular points in time in the future from information gathered from SOP, Stock Control, BOM and POP. This option is called “MRP Details” and is available within SOP Processing, Stock Control, Purchase Order Processing and the MRP module.

Multiple cost prices can be set for a Supplier Product based on Quantity Breaks values. These multiple costs will be recognised by Purchase Order Processing and MRP Purchase Orders.

Stock items can be easily excluded from the MRP processing by warehouse, stock category or by individual stock code.

The MRP module is parameter driven and has been developed and continues to be developed based on the requirements of customers.

|